This is an ongoing blog post series covering tools in the makerspace one can purchase for their at-home making needs.

This is an educational post and I have not been sponsored by any of these companies in any way.

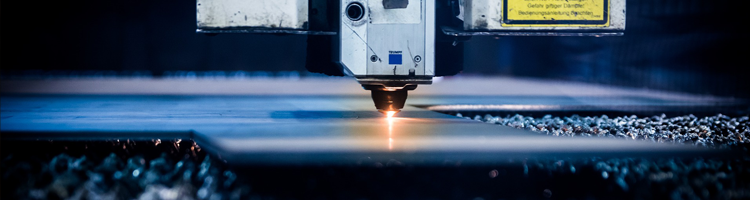

In my last three years working in shops and makerspace, it has come to my belief that the heart of the space is the laser cutter. They are versatile tools, and a key to rapid fabrication and prototyping of multiple items in one go. The downside is…they can be very expensive.

In my previous post, I have covered 3D printers, even highlighting some 3-in-1s Like the Zmorph XV, Snapmaker, and da Vinci Pro. Many are affordable and are a laser engraver, 3D printer and miniature CNC mill. They are a viable option but may you want a standalone laser cutter.

I will be covering a few prosumer ones for use at home, as well as some industrial grade cutters. Unfortunately there seems to be more of those than machines for the hobbyist or maker. However in the future there may be many more developed.

My post is by no means a comprehensive, be-all, but a mixed bag of machines I’ve scoured the internet and checked out. Be aware the prices I list are their starting price, meaning addons, peripherals, upgrades, and shipping will add on the price.

Before We Begin:

A Word of Warning:

A laser cutter beam is a beam of light that goes on infinitely– that can and will cut things! Having one in an open containment situation could lead to potential dangers. Please be advised when purchasing these kinds of laser cutters, and have a plan for housing and operating them.

Furthermore, this also does not guarantee your eyes are protected as well! Please make sure to find laser level/laser grade glasses/laser safety goggles when purchasing a laser cutter. You can purchase them at hardware stores like Home Depot or Lowes, as well as online by suppliers. Like the cutters, make sure it’s a reputable seller– these are your eyes after all!

Another issue is ventilation and air extraction. Some systems have internal ventilation and cooling systems, some have external cooling systems, or in the case of many of the open frame models– do not ventilate at all. MAKE SURE YOU ARE PUTTING YOUR MACHINE IN A ROOM WITH VENTILATION OPEN WINDOW. Some models will come with a ventilation system you can purchase extra if that is not the case. There are some DIY options for fume extractors, but fume extractors machines can be purchased.

In my opinion the open frame laser cutters are dangerous and I would personally advise against them, however I understand these kits are on the more affordable side of things– and I am sharing them simply to illustrate the different kinds of laser machines available.

K40 machines are under $1000 USD usually, but could be a gamble. Many overstate specifications, use shoddily electronics, or are outright counterfeits that are unsafe to use. If you’re looking to just ready to go, there are other options, albeit more expensive. If you don’t mind being a bit more handy and doing a lot more research and don’t mind upgrading your machine yourself…purchase at your own risk. I will share some resources on K40s at the bottom of this post.

Do your research, have a plan, and err on the side of safety. And never, never NEVER leave your machine running unattended!

Many of these machines use proprietary software for exporting, and while you can use them to create your pieces, you can very much still use Illustrator or Inkscape to create vector artwork and import it in. Very likely using an SVG file would work best, as I am unsure if any can import EPS or AI files.

Diode vs CO2 Lasers

- A Diode Laser or Semiconductor Laser uses a semiconductor to create the light for the laser. This is not too different from the kinds of laser used for disk readers, simply focused enough to engrave (and in some cases cut). Chances are if your machine is just an open frame (like the 3-in-1 sets), it’s like a diode laser. They tend to have a lower wattage as well.

- A CO2 Laser uses electrically charged carbon dioxide gas to generate the light of the laser and is directed by mirrors to create a cut. These are the ones that need ventilation and are common for industrial grade machines. The Epilog laser cutter in our makerspace is a CO2 laser.

- A Helium-Neon Laser is like a CO2 laser, but instead uses a mix of helium and neon. Plasma cutters use this mix to generate their cutting plasma as well. Again, these are more industrial grade machines that likely aren’t for at-home use.

- A Fiber Laser uses a fiber optic filament coated in rare elements to generate a beam. These machines can be used to cut materials like metals and the like, however few machines like these are on the market and are very, very expensive.

What’s in a Watt?

When looking for a laser cutter, you may see a number of wattage alongside the specifications. The wattage determines the strength of the laser cutter and speed of the etch. This also determines the thickness limit of your materials. Anything under 15 Watts can cut very thin material like paper– but can engrave. If cutting is what you are looking for, you may want to look for a machine that is 30 Watts or higher.

For the Hobbyist:

These are non industrial laser machines, meant for use at home or in a garage. Most of them a diode based lasers, and are in the open, unlike CO2 lasers. Many are considered “engravers” but can cut some materials. Some may come ready to use out of the box, other kits may need to be built by you, or need peripherals so keep an eye out when you’re doing your research.

Many of them use proprietary mobile device based apps that support vector work, but will need an internet connection to work, and are not recommended for jobs longer than an hour (personally I’d say 30 minutes is even too much bit it depends on the design.)

Cubiio: This tiny little cube is a 1.6W diode laser engraver. It was recently targeted by scammers selling copycats at very low-cost, and thus has been given a bit of a bad rap. Further concern is many of the demo videos show it being used in the open (y i k e s), which isn’t entirely safe. Cubiio has made some attempt to make it safe. It comes with a pair of laser goggles, and the app is password protected. It also has motion detection that will turn off the machine if bumped. It also emits a beeping sound while operating.

There are some cons. It still needs an internet connection and the machine app can only be run through your mobile app (but it does have a micro SD card slot as well, and uses gcode!). The site’s material listing isn’t entirely correct and has issues working with round/circular shapes. Some of the website (particularly the store) is still in Chinese– so be careful when going through translator apps if you cannot read it. Alignment is wholly eyeball based, and may lead to inaccuracy, but can be solved with a jig if you’re feeling particularly dedicated.

At $422 USD ($560 USD with the enclosure), it is affordable compared to some of the other machines in this post, but it isn’t a true laser cutter/

Laserpecker: Similar to Cubiio, this is a small 0.5W diode laser that can be mounted on a tripod (but not advised), and has the option of the small safety enclosure as well. It’s mobile device based app also has a password lock for operational safety as well as motion detection and overheating protection. It can also be powered by a USB-C power bank.

At $300 for the standalone machine, $400 USD for the L1 kit, and $460 USD for the L1 Pro kit it is slightly more affordable than the Cubiio, and also comes with extras like a case and a autofocus centering stand attachment. It also seems to lack the issue with round shapes like Cubiio has as well.

Fabool: Unlike the previous engravers, Fabool Mini is a kit in which you put together yourself. It is an open frame (!) with no safety enclosure, and the safety bed and exhaust fan are additional purchases. It is a 1.6W or 3.5W diode laser (depending on the version), and the app works both on the computer and for mobile devices.The 1.6W goes for $550 USD and the 3.5W goes for $800– with an additional $50 USD for the bed, $120 USD for the exhaust fan, and $500 for the particle filter.

For the version with an actual enclosure, it is $800 USD for the 1.6W and $1050 USD for the 3.5W version.

Universal Engraver: Universal has several different models of engravers, from the small 1.6W like Laserpecker and Cubiio for $500 USD, and series of engravers for wood and leather betweein $300 USD to $1100 USD. They also have different machines for cylindrical, glass, and metal. It’s worth a look!

In short: If you’re looking for something you might use now and again, working on a smaller scale, and just engraving and not cutting anything thicker than paper, then these are the machines to go for. My advice if purchasing these ones… work with an open window and box fan! And while the Fabool is listed, personally I think after buying all the peripherals, it is about half the price of a basic laser cutter, and at that point may consider saving up for something that can actually cut anything more than paper.

If you are working primarily in paper, I might recommend a vinyl cutter instead. They are half the price and work very well for paper without the potential fire hazard. I will be writing up a post on some in the future!

My Pick: The Laserpecker. I like that it’s portable, comes with the safety enclosure and is somewhat affordable for a simple laser engraver.

For the Maker:

These were made for small to mid range scale of fabrication; i.e. making jewelry for your online story, props, or something you plan on using frequently in your work. Like the hobbyist, these machines are limited to thinner materials, but have more range than the hobbyist machines.

Usually you can cut anything up to ¼ (.25) inches with these machines.

Glowforge: This is the machine I’ve heard and seen most often. A 40 Watt CO2 Laser, it can cut materials up to 1/4 (0.25) inch, as well as etch. Setup is easy and beginner friendly, no need to build from scratch. It does need to be vented, and comes with an attachment to stick in a window. An air filter system can be purchased for extra if you’re space is without a window. Autofocus is already in the machine, as is an air assist system.

Cons to the Glowforge is the proprietary software it is browser based and needs an internet connection to work. But it is also cloud based, so the firmware updates are automatic.

The Glowforge Basic (30W) starts at $2500 USD and the Pro (45W) for $6000 USD. While pricey, it has been a favorable machine among makers, and the closest to an industrial machine for under $10,000. Its onboarding is fairly simple and the app is easy for beginners to use as well. It already has autofocus available as an option, should you be the kind inclined to use it.

Beamo: Flux Beamo is a hybrid CO2/diode laser, this at 30W. It is also a smaller bed size than the Glowforge. The standard Beamo begins at $1900 USD, and the larger 50W Beambox goes for $3300 USD. Like Glowforge it comes with an optional air venting system for windowless spaces for $800 USD. The Beambox at the very least is ready to go from the box with little to no tuning, and at 50W is on par with some of the lower end industrial laser cutters like Epilog. Another pro is it has USB and Ethernet connection, meaning it can be used offline.

More cons, it comes with its own proprietary software as well, but seems to have a computer version. You can purchase an autofocus module extra that you will need to attach on your own. (I alway manually focus my materials, so it’s not a huge make or break for me, but it might be for you!) Ventilation is a simple air with no filtration, but has a built in air assist module.

My opinion: Invest in the Flux Air when buying the Beamo. It’s only $800 more and collectively is still about the price of the Glowforge Pro.

Laserbox (Now xTool): Is a 40W CO2 laser engraver/cutter on the same level as to the Glowforge and Beamo. While it has simple proprietary software for exporting, it has a neat feature where you can draw on your material and with a built in camera (!), use the software to etch and cut. Like Beamo, it too has USB and Ethernet connection, meaning it can be used offline as well. Laserbox also has an internal air assists and autofocus as well.

Laserbox Basic starts at $4000 USD, and the optional (but recommended) exhaust fan for $300 USD. The Laserbox Pro goes for $6000 USD and comes with the filter box, and some materials to experiment with.

Dremel DigiLab: Camera, software can engrave hand drawn items. 40W CO2 Laser, internal air assist and autofocus capabilities. Ethernet for offline or Wireless connection, browser based software

The LC40 standalone is $6500 USD, the exhaust fan can be added on for $300 USD. The LC40 and Filtration Bundle is $8500 USD, making it starting to work on par with industrial level systems.

Muse: Full Spectrum Laser Muse has both a 40W and 45W CO2 version for the smaller desktop cutters, as well as some more industrial level machines. Muse Core has no autofocus ability, and needs external air assist with a compressor (not included). You will need to purchase an air compressor, water pump and exhaust fan. The 3D Autofocus Bunder comes with the machine, air compressor, water cooling solution and air compressor, and as the name suggests has autofocus abilities.

The export software is browser based, and can be used both wireless through wifi or offline through an ethernet cable. The Core goes for $3500 USD for the 40W, and $3750 USD for the 45W. And for the bundle, it is $6500 USD for the 40W, and $6750 USD for the 45W.

Universal Engraver: While mostly providing laser engravers, Universal has a 50W CO2 laser engraver and cutter for $8000 USD. It comes with Corel Draw– Corel’s vector editing software similar to Adobe Illustrator. It can be used offline, and does not give any details about air assist or autofocus capabilities.

Orion Motor Tech: Orion is an oddity. Their actual website doesn’t link any of the laser cutters on their site,only showing their mechanic’s tools, but they are all available on Amazon. They have 40W CO2 machines starting at $500 USD, to 100W machines for $3200 US. This is my first time hearing of them though, and have very little from their social media and Amazon Reviews. I would take care in looking into one of these machines, similar to the K40 machines.

In Short: All of these are large investments, and can do a wide array of materials. Just make sure what peripherals you need to purchase and what comes with the machines when purchasing them.

My Pick: The Laserbox or the Beamo Beambox seems like the best pick for my personal taste, with the Glowforge as a decent third.

Industrial Cutters:

These are the heavy duty CO2 or Helium-Neon cutters that you might see in some makerspaces or digital fabrication studios. Some few intrepid people may even invest in these machines for personal use. These all usually need an outside air compressor for air assist capabilities, and need a special air system connected to their machine for fume extraction– usually on top of a secondary fume extractor for use. These, unlike many of the desktop cutters, can be used offline via an ethernet connection (usually).

I don’t expect anyone reading this to be looking into purchasing these, but it’s good to know what’s out there.

Epilog: Epilog machines are the ones I know most about. These are the ones I started on in school, and we have an Epilog in the makerspace. They are CO2 lasers and make many models of varying size and power, starting with the 30W. They have autofocus capabilities, and need an air compressor for the air assist.

The most “affordable” options are the Epilog Zing, a 30W cutter, starting at $8000 USD, the Legend Mini series at $18,000, and the Legend Helix Line at $21,000 USD. They also have a fiber optic line, but you can request a price– which usually means they are very pricy.

Universal Laser Systems: Not to be confused with Universal Engraving, this group provides industrial laser cutters as well. You need to contact them for a quote on their machines, but I’ll safely guess they are between $10,000-$20,000 USD.

Boss: Boss straddles the line between industrial and desktop by way of price, their entry level LS-1416 50W CO2 laser starts at $4000 USD, and can be upgraded to 70W. The most advanced of their hobby lasers is the LS-1630 65W CO2 (can be upgraded to 100W) at $7000 USD.

Their LS-2436 is the lower end of their expert lasers. The 65W CO2 laser starts at $10,000, but has add ons and can be upgraded to 150W. They also have metal cutter and fiber optic cutters as well.

All models have air assist and autofocus capabilities, and come with its own software. Upgrades and addons can be additionally purchased.

Full Spectrum Laser: We already covered the Muse desktop series, but Full Spectrum has their PS24 Pro Series. This 90W CO2 laser starts at $9000 USD. The PS36 Pro has a 90W and 120W version for $12,000 USD and $15,000 USD respectively. Their PS48 series comes in 90W, 120, and 150W at $13,000 USD, $16,000 USD, and $19,000 USD respectively.

All have autofocus capabilities and air assist via an external air compressor. They use their own proprietary software for export. Additional add ons can or will need to be purchased additionally.

Rabbit: Rabbit has a wide variety of industrial grade laser cutters starting with a 40W cutter at $5700 USD to a large 4 foot by 6 foot laser 80W CNC for $14, 600 USD. Autofocus and air assist is available in the closed models, and export software can be purchased additionally.

Grizzly: Grizzly has a whole suite of industrial tools from CNCs to Mills and Lathes and more. Their “Laser CNC” is a CO2 laser cutter and engraver like the rest. Their $3400 USD 60W benchtop machine is comparable to the likes of Glowforge, Beamo, and Lightbox. They also have a 150W for $7,500 USD, and a $150W 9875 USD industrial machine.

The Benchtop model is manual focus only, the industrial ones have autofocus capabilities. All have external air assist, and come with RDWorks software.

In Short: These are for the experts, for those with heavy laser use under their belt. Not exactly something to invest in and jump in on right away. Look through Specification Manuals, ask for quotes, talk to the representatives and distributors before committing to any of these. These are hardy machines and if taken care right don’t really need as much maintenance, but parts and repairs will inevitably be just as much an investment as the machine. On the other hand, large wattage machines can cut a larger array of materials and thickness. (60W can only cut about .25 inches at best, a 100 W can do .5 inches to .75 to 1 inch entirely).

My Pick: Because of my familiarity with the machines leave me a bit biased, I will say Epilog. Full Spectrum is likely my second choice. Again, I can only dream of owning one of these machines on my own– but I can still dream!

Further Research:

As I’ve said a billion times, these machines are not cheap, and will be a commitment. Compare and contrast to your needs for the best one for you. Above is just the tip of the iceberg, but great ways to start on your laser cutter adventure. However be mindful of the following in your searching:

- Price Point/Budget

- Ready-to-Go or Kit

- Wattage

- Ventilation Type

- External or Internal cooling

- Auto or Manual Focusing

- Air assist (and weather or not the air compressor is extra)

- Material Guidelines

- Active Bed Size

- Ease of Maintenance

- Level and Quality of support from the company

- Can the app software import my file format? (AI, EPS, SVG)

And don’t forget to look into purchasing the following as well:

- Laser Safety Goggles/Glasses

- Fume Extractor

- Fire Extinguisher (preferably a gas-based one when working with CO2 lasers)

Below are more links for you to check out, as well as resources for those who think they want to commit to a K40 machine.

Good Luck and happy hunting!

General Info:

K40 Research: